From firewalls to industrial control systems (ICS), operational technology (OT) powers the physical processes behind critical infrastructure.

Digital environments face greater risks as they increasingly rely on the Internet of Things (IoT) and other technologies to get real-time insights. That means security is key to keeping them running.

OT cybersecurity strategies help mitigate risk by protecting the hardware, software, networks and data in these environments.

What Is Operational Technology Security?

OT security refers to the practices, security controls, and technologies used to protect ICS and other cyber physical systems from threats. Unlike traditional information technology environments that prioritize data confidentiality, OT environments focus on integrity and availability.

OT systems control machinery, chemical processes, power grids, and other elements of critical infrastructure. Some of the main security components that protect these systems include:

- Supervisory control and data acquisition (SCADA): SCADA monitors and controls geographically distributed assets, such as water distribution networks.

- Distributed control systems (DCS): These systems automate plant processes through sensors and semi-automated controllers, such as the ABB Ability System 800xA used for offshore drilling in the oil and gas industry.

- Industrial Internet of Things (IIoT): IIoT refers to the infrastructure of networks and sensors that collect and transmit data for real-time monitoring and optimization, such as machine sensors in manufacturing plants.

- Programmable logic controllers (PLC): These automated processes follow a simple logic, such as traffic lights that safely direct cars and other vehicles at an intersection. Some are even equipped with sensors to grant priority to emergency vehicles.

- Remote terminal units (RTU): Microprocessor-based devices like these monitor and collect data and transmit them to SCADA systems, such as equipment used in environmental monitoring stations.

Given the nature of organizations implementing cybersecurity for OT, these and other systems play a critical role in public safety. One extreme example is a nuclear reactor’s cooling systems. If the surrounding systems were hacked or infiltrated, the impacts would be catastrophic.

Differences Between Information Technology and Operational Technology Security

While both information technology (IT) and OT systems require cybersecurity, they serve very different purposes. IT protects the confidentiality, integrity, and availability of data and networks across digital assets. OT prioritizes the reliability, safety, and continuity of physical processes. OT teams make sure industrial systems like PLCs and SCADA continue to work as planned with minimal or no disruption.

In the past, the risk of disruption mostly came from damage to physical components or other operational concerns. But cyberattacks are a growing issue. A 2021 ransomware attack on Colonial Pipeline in the United States, for example, disrupted 45% of fuel sources on the East Coast for almost a week. This led to widespread panic and long lines at the gas pumps.

These and other threats like them have led to a convergence between IT and OT security for dual coverage. Coordinated security controls, like unified monitoring and network segmentation, helps organizations defend both data-centric and process-based attacks. This leads to improved process reliability, business continuity, and even national security.

What Are Some Challenges in OT Cybersecurity?

Organizations implementing security for OT face similar risks to those only focused on IT security. But there are also some unique challenges:

- Legacy systems: Many industrial environments rely on outdated technology, like clunky hardware, discontinued operating systems, and proprietary communications protocols. IT teams often set these up decades ago, making them difficult to integrate, upgrade, and patch.

- Tension between security and safety: Patching or updating industrial controllers and other cyber physical systems requires downtime, but this can lead to cost and safety concerns. This conflict makes OT security a landmine for difficult—and delayed—decisions.

- Lack of visibility: Despite the IIoT and other developments, it’s still tough to monitor and analyze data from so many devices and systems. Isolated networks, disparate devices, and other tech silos create security blind spots.

Importance of Operational Technology Security

At an organizational level, here are some of the benefits of OT:

- Continuous monitoring: Real-time visibility into device health and network traffic can detect maintenance issues and infiltrations before things spiral out of control.

- Safety and reliability: Protecting the tools that keep critical infrastructure running enhances machine safety, maintains consumer trust, and supports the public.

- Reduced downtime: Proactive vulnerability management and incident response can anticipate attacks and maintain operational continuity, regardless of cyber threats.

- Regulatory compliance: Organizations in this industry often face tighter regulations. That means they often need to employ OT security to meet safety requirements and maintain licenses.

4 Best Practices for Operational Technology Security

OT security is complex, especially when combined with IT security. Organizations can make implementation easier—and more successful—with these best practices:

1. Implement Robust Asset Management

Strong asset management begins with a thorough inventory of the hardware, software, and other elements of the infrastructure. Track and categorize all connected devices and installed software, and create protocols around keeping this list updated. This reduces many of the blindspots that contribute to lack of visibility.

2. Enforce Zero Trust Remote Access

OT cybersecurity is one of the best use cases for Zero Trust enforcement. Organizations must verify every request for access to the systems, especially privileged or admin access. Security tools like multifactor authentication, passkeys, and continuous monitoring can reduce the chances of hackers accessing industrial control systems—even if they have log-in credentials.

3. Apply Network Segmentation

Separating IT and OT networks with firewalls, intrusion detection systems, and secure protocols also minimizes risk. If a hacker gets into one system or network, segmentation makes it more difficult for them to move into another.

4. Strategically Modernize Systems

Many organizations use legacy systems well beyond their secure lifecycle. For example, when Microsoft discontinued support for Windows XP in 2014, NBC news reported that 76% of respondents to a survey continued to use XP operating systems. One unsecured device can create an easy gateway into other systems, so take steps to modernize.

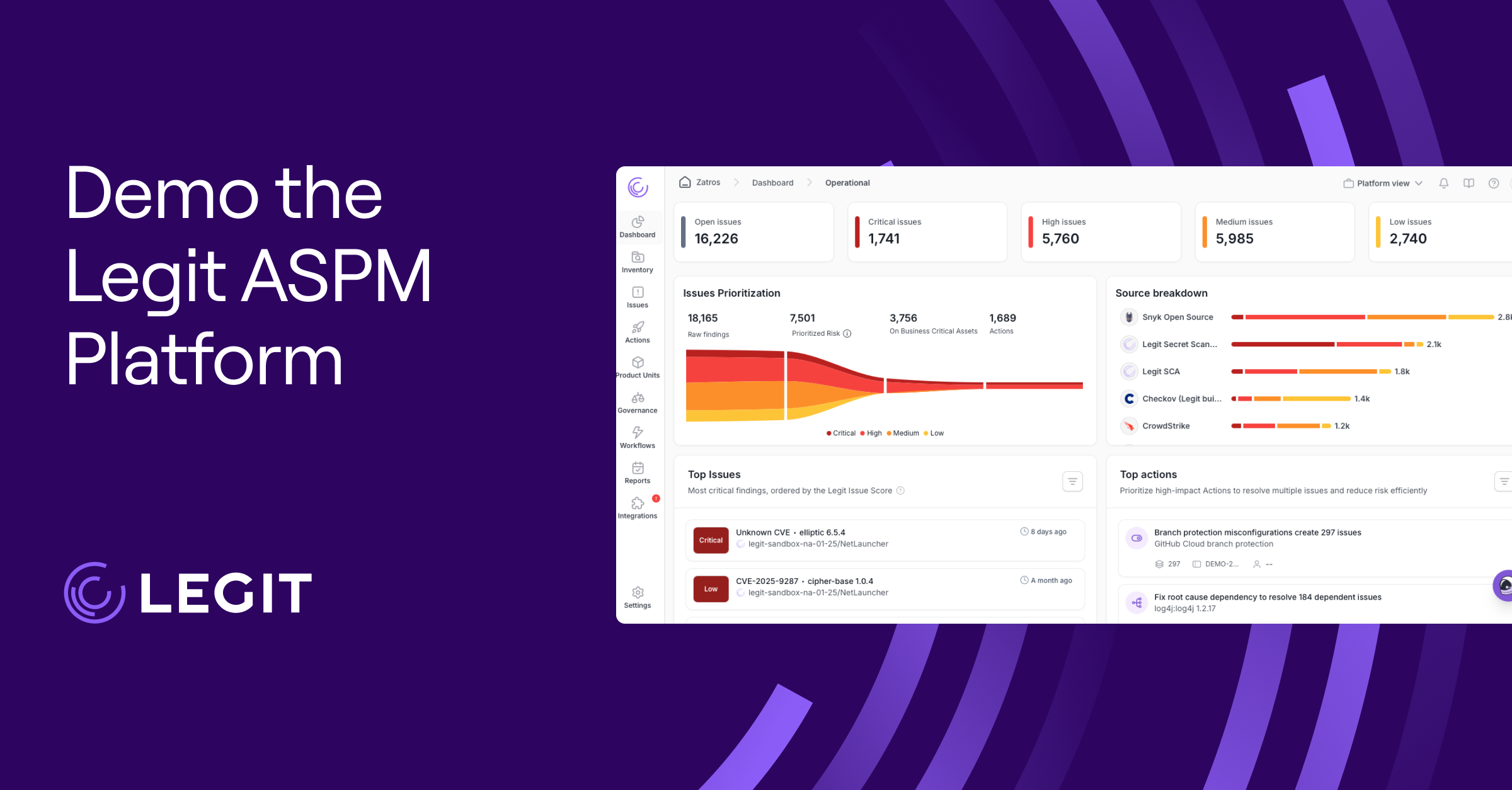

Protect Your OT Systems With Legit Security

Integrating security early reduces the risk of introducing vulnerabilities into critical infrastructure from automation tools, protocols, and connected devices.

Strengthen OT security and the software supply chain with Legit Security. Legit provides enterprise-grade secrets scanning, giving you the visibility and remediation capabilities you need to keep the software lifecycle secure. Reduce risk without slowing down delivery.

Are you ready to build safer and more resilient operations? Request a demo to get started.

Download our new whitepaper.